- 1772

- 产品价格:9.00 元/千克 起

- 发货地址:广东东莞樟木头 包装说明:不限

- 产品数量:9999.00 千克产品规格:不限

- 信息编号:187465564公司编号:15374994

- 蒋先生 销售 微信 182006460..

- 进入店铺 在线咨询 QQ咨询 在线询价

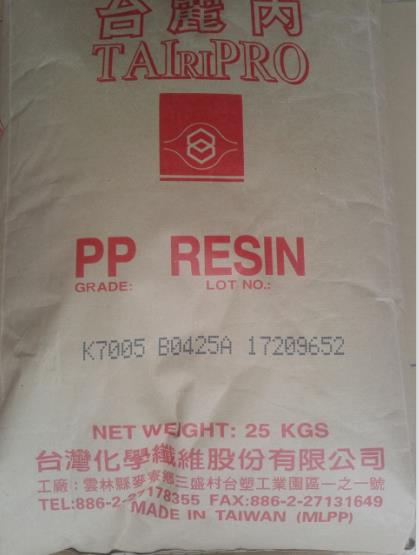

PP K8009台化批发 货源充足

- 相关产品:

pp

台化塑膠事業部原為化工第二事業部,早期是為配合台塑企業六輕計劃上下游相關產業之發展而設立,當時負責芳香烴、苯乙烯系列之建廠籌劃,由於六輕計劃案廠址之滯延,乃決定由下游之聚苯乙烯(Polystyrene)先著手建廠,將產品導入市場,以利將來上游產品之產銷。

PP化学改性:通过共聚改性、交联改性、接枝改性、添加成核剂等使PP(聚丙烯)高分子组分与大分子结构或晶体构型发生改变而提高其机械性能、耐热性、耐老化性等性能,提升其综合性能、扩大其应用领域

The tensile strength and rigidity of PP are good, but the impact strength is poor, especially at low temperature. In addition, if there is orientation or stress in the molding process, the impact strength will be significantly reduced. Although the impact strength is poor, its mechanical properties can compete with high cost engineering plastics in many fields after filling or strengthening. The surface hardness of PP is lower than that of PE. When the crystallinity is high, the hardness also increases, but it is still lower than PVC, PS, ABS and so on. Among the five general plastics, PP has the best heat resistance. PP plastic products can work at 100 ℃ for a long time. Without external force, PP products will not deform when heated to 150 ℃

The comprehensive properties of PP are better than that of PE. PP products are light in weight, good in toughness and good in chemical resistance. Disadvantages of PP: low dimensional accuracy, insufficient rigidity, poor weather resistance, easy to produce "copper damage", it has the phenomenon of t shrinkage, easy aging, brittle, easy deformation after demoulding. In daily life, the commonly used fresh-kee box is made of PP material. In order to prevent photoaging, it is necessary to add UV absorber into PP, which can transform the UV absorption of 290 ~ 400nm into non destructive long wavelength light. For the PP plastic products buried in the soil or used indoors in the dark, only the main and auxiliary antioxidants can be added, and the ultraviolet absorber is not needed. The shrinkage and crystallinity of PP are lower than that of PE. PP has a certain permeability to oxygen, carbon dioxide and water vapor. Compared with nylon PA and polyester PET, PP is much worse than nylon PA and polyester PET, but it is much worse for high barrier plastics such as PVDC and EVOH. But compared with other non plastic materials, its air tightness is quite good. The air tightness can be greatly improved by adding barrier materials or coating barrier plastics on the surface. PP is a non-polar polymer with good properties

There are tertiary carbon atoms in PP molecules, which are easily broken and degraded under the action of light and heat. PP without stabilizer will become brittle when heated at 150 ℃ for more than half an hour or exed to sunlight for 12 days. PP powder without stabilizer will degrade seriously and emit obvious acid taste when stored indoors for 4 months. Adding more than 0.2% antioxidant before PP powder granulation can effectively prevent degradation and aging of PP during processing and use. Antioxidants can be divided into two categories: free radical chain reaction Terminator (also known as the main antioxidant) and peroxide decomition agent (also known as auxiliary antioxidant). The reasonable combination of the main and auxiliary antioxidants will play a good synergistic effect. If PP is cooled slowly in the air after leaving the die, it will produce larger grains and the transparency of the product is low

Taihua PP resin (tiripro? PP resin) adopts the CHISSO gas-phase process method of Japan, uses a new generation of high activity catalyst and strict quality management system, with an annual output of 510000 tons. It can produce homopolymer and copolymer, supply injection, extrusion, fiber, blowing, vacuum molding and other processing industries. It is widely used in household appliances, auto parts, food packaging, toys and people's livelihood products.

联系电话是0769-89977070, 主要经营晶宏塑胶原料有限公司长期低价供应各种品牌,各种系列,各种型号的塑料原料。绝对保证质量,物美价优。欲要了解更多的详情,请在本网页留言或者通过电话联系我,金红塑料将本着诚信为本,客户至上的原则竭力为您提供最优质的服务。。

单位注册资金单位注册资金人民币 100 - 250 万元。